WhatsApp)

WhatsApp)

Cement grinding mill and cement mill including raw materials, equipment commonly ... Which has a highquality, ... Figure 1 depicts a typical flow chart of raw meal.

Coal Mill . .. Figure 3: Schematic of cement manufacturing with energy consumption. ... The emissions from the kiln and the raw mill are convoyed to the same stack .

How to determine the intake port surface distance to mill when the heads are milled

Indirect Coal Firing Mill Figure 23 ... A detailed description on the efficiency improvement of the mill itself is provided above in the paragraph on the raw mill.

In the wet process, water is added to the raw mill during the grinding of the raw materials in ..... Alternatively, ... (Figure 1). ..... (b) ...

Reducing energy consumption of a raw mill in cement industry. Author links open the author workspace. Adem Atmaca Opens the author .

Inside the mill (see Figure) the grinding process of the fed raw coal is . Later the mill was equipped with a dynamic classifier, type HEPH6. Bowl Mills.

This concept reduced the cost of the raw material transport, the mill ... (Figure 7 shows the working VERTICAL ROLLER MILL ... roller module of Loesche mill ...

CEMENT INDUSTRY. Raw mill Since the wet process has a simple system, it is important to enhance ... 15 Cydone Collector c. Indirect Coal Firing Mill Figure 23 ...

Jun 15, 2016· Many researchers have done experiments on pelleting of raw and ... Schematic of a laboratory scale flat die pellet mill at ... Figure 7 shows the ...

Scribd is the world''s largest social ... Cement Process Energy Saving. ... Open Circuit Dryer and raw mill are installed separately. Figure 4 Dry Process Raw ...

Stainless steel mill products: ... as shown in figure 1: (1) melting or refining raw steel, (2) casting the raw steel into semifinished forms, (3) hotrolling the

Effect of Size Reduction Parameters in ... Figure 1. L1A Fitz Mill ... Effect of Size Reduction Parameters in Pharmaceutical Manufacturing Process ...

Vertical Roller Mill State of the Art Raw ... These factors require conveyor systems not necessary for the FIGURE 5: Raw grinding alternatives ...

Effective Optimization of the Control System for the Cement Raw Meal Mixing Process: Simulating the Effect of the Process Parameters on the Product Homogeneity

factors affecting raw material inventory management in ... factors affecting raw material inventory management in ... figure mill location map 77 vm .

Figure University of Toronto. Title: ... CEMENT GRINDING IN A VERTICAL ROLLER MILL The differences between raw and cement grinding have been well documented in ...

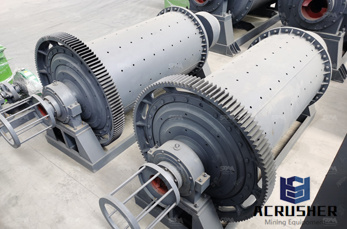

Raw material mill products are mainly used for grinding of cement raw materials, also applies to the metallurgical, chemical, electric power and other industrial and ...

Domestic Supply of Raw Cotton. . Figure 37 Cotton Market Share at Mills. Get ... SEO, SEM,SNS Promotion Mill Solutions (Ball mill, Vertical Raw Mill, ...

Portland Cement Manufacturing ... in the figure, ... water is added to the raw mill during the grinding of the raw materials in

Figure 1 Raw Milk Consumption among Patients with Non ... 1 Jan 2014 ... Raw milk has frequently been identified as the source of foodborne illness outbreaks ...

Mermaids at Mill Point Fresh. 52 likes. Mill Point Fresh offers daily groceries, coffee, fish and chips, raw food and an array of organic and gluten free...

Figure 2. Block diagram of the corrected control object. Where G volumetric flow rate of raw coal, G1 volumetric flow rate of the dry part of the supply of

loesche raw mill. Madras Cement will ... of all raw mill systems. High efficiency . FIGURE 1: ... Working of loesche Mill: Raw material comes into raw mill from ...

WhatsApp)

WhatsApp)