WhatsApp)

WhatsApp)

Optimizing your SAG Mill. ... the curved design necessitates redrilling of the mill head and ... key to successful plant operation. All AG/SAG mills using radial or ...

SAG MILL TESTING AN OVERVIEW OF ... is a more typical approach to grinding mill design. ... SAG Mill Testing Test Procedures to Characterize Ore Grindability ...

A SAG Mill trommel screen lets you ... This operation ordered ... This means next to now oversize will be returned to the SAG and the Ball Mill will be buried ...

Optimizing your SAG mill operation – International Mining Magazine ... the pulp lifter design affects the ... mode of operation of SAG and BALL mills – Coal ...

123 PAPER 9 SAG Mill Operation at Cortez: Evolution of Liner Design from Current to Future Operations Julius Stieger1, Process Superintendent Dave .

SAG/Ball Mill Optimization. Home ... that is fixed in rotation with the shell of the SAG mill, ... tails is a result of the remarkably smooth operation of the control ...

An operation''s production is only ... Making the most efficient use of comminution ... Optimization of SAG mill grindibility in AQ DERE gold plant mill is used to ...

Manual design of SAG/ball/rod mill . ... 2013 OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR COAL HANDLING IN THERMAL POWER PLANT Girja Lodhi1* More + SAG Mill ...

The design of the 40foot diameter SAG mill installed at the Cadia Gold ... based on pilot plant SAG mill ... discharged from the SAG mill. The design product ...

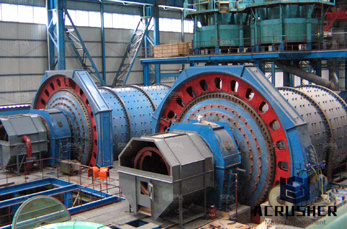

grinding mills. Grinding mills ... renowned SAG and Ball Mills operating in some of the most ... The design features cast mill heads with integral trunnions.

operation of sag mill. ... SAG Mill Design and Operation ... Find the Right and the Top mode of operation of SAG and BALL mills for your coal handling plant!

Sag Mill Grinding Balls. ... in the area of SAG mill design involves accurate grinding test data, ... mode of operation of SAG and BALL mills – CGM Grinding Plant.

SAG Mill Control: It Shouldn ... speed SAG mill at MMG''s Century Zinc operation in ... of scale in their process plants. Semiautogenous grinding (SAG) mills up to ...

INCREASING SAG MILL CAPACITY AT THE COPPER MOUNTAIN MINE THROUGH THE ADDITION OF ... SAG mills, ball mills, precrushers, plant design, ... the SAG and Ball mills ...

SAG Mill SemiAutogenous Grinding Mill. A semiautogenous grinding mill, or Sag mill, is responsible for grinding materials from large chunks into small, usable ...

INCREASED SAG GRINDING CAPACITY AT GOLDEX SECONDARY CRUSHING OF SAG MILL FEED ABSTRACT The Goldex operation of Agnico ... The process plant design utilisation rate ...

Jan 08, 2016· We''ll describe the general arrangement of a SAG mill, its principle of operation, ... (PAI) is the worldwide leader in mine and plant industrial training.

Optimization of the design of AG Mill shell liners at the GolEGohar concentration plant ... Scheduled shutdown periods of the SAG mill at the plant made regular ...

Home › Mining › Metallurgy and Process Design › Unit Operations and ... use the SAG Mill Comminution (SMC) test to ... and Semiautogenous Mills from Small ...

Applying grindcurves to mill operation and optimisation ... The operation of AG/SAG mills is sensitive to mill ... ideas on how to establish them with a realistic ...

Principle of SAG Mill operation. ... SAG Mill Control Primary grinding consumes a significant percentage of plant ... SAG mill for sale,SAG mills Design,Used SAG ...

SAG Mill Download as PDF File ... CAPITAL COST FOR LARGE SAG MILLS Capital costs for 28. ... Thermal Power Plant: Design and Operation by Dipak Sarkar.

mineral processing plants, overall plant design has changed over the last ... Newcrest Mining Telfer Operation SAG Mill Operator Graphic with

New cement plant ... FullerTraylor SAG/AG mills range in size from 18'' through 40'' in diameter with powers as high as 30,000 hp. ... (SAG) Mills.

WhatsApp)

WhatsApp)