WhatsApp)

WhatsApp)

Milling Efficiency Balls Size ... The model of the relative capacity as a function of circulating load and classification efficiency for secondary ball mill ...

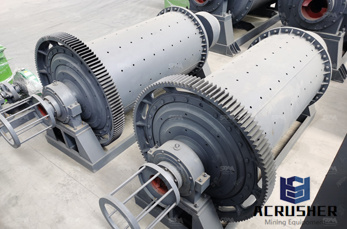

A ball mill can grind and homogenize small sample volumes down to the nano range. The Emax is an entirely new type of ball mill for high energy input.

Five Steps to Increase Ball Mill Efficiency College Essays wang The ball mill is the key equipment for grinding after the crushing process, which is widely used ...

Calculate and Select Ball Mill Ball Size for ... Find ball mill efficiency calculations on the web, the site is foucs on mining equipment tech. Readmore.

Moisture Removing Increasing Efficiency in "Ball Mill ... and how to increase the efficiency of ball mill. ... Stone size For two chamber ball mill

An improvement in efficiency of 5% for cement produced in those mills would increase. Get Price. Ball size distribution for the maximum ... Ball mill Wikipedia. A ...

Effect of ball size and powder loading on the milling efficiency of a laboratoryscale ... size, ball mill was ... powder loading on the milling efficiency, ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

The energy efficiency of ball milling ... data to provide an assessment of the energy efficiency of ball ... to the ball mill at any other size ...

Ball Mill Costing Calculation . ... crushing ball mill size calculation invest cost. ... ball mill efficiency calculations OneMine Mining and ...

Ball Grinding Efficiency ... ball mill efficiency improvement ... Relationship of Media Size and Grinding Efficiency of Ball Mill .

Ball Mill Costing Calculation . ... ball mill efficiency calculations OneMine Mining and ... ... the ball size in the ball mill ...

It is well known that ball milling efficiency ... mill discharge product size in relation to the ... media in the mill by looking at the mill grinding efficiency. At

W is the work index measured in a laboratory ball mill ... F 80 is the mill circuit feed size in ... the greater the grinding efficiency. Autogenous mill ...

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL ... Ball size distribution inside an industrial mill was ... Figure Ball size distribution along the mill length ...

for Accident Prevention Design for Energy Efficiency ... What is ball milling? A ball mill is a type of grinder used to grind ... Material feed size: ≤ 8 mm

Official FullText Paper (PDF): Effect of Ball Size and Powder Loading on the Milling Efficiency of a LaboratoryScale Wet Ball Mill

effects of grinding media shapes on ball mill grinding. Ball size distribution inside an industrial mill was analysed in terms of ..... Grinding is generally an ...

Grinding Efficiency In Ball Mill. ... ball mill efficiency is based on a work index value developed ... Relationship of Media Size and Grinding Efficiency of Ball Mill.

Crusher Machine For Sale. ... ball mill efficiency calculations manufacturer in Shanghai, ... law which relates mill power and mill size and mill

Size Reduction Equipment | Paul O. Abbé. Steel Ball Mills. Benefits of Tumble Milling: 1. HIGH EFFICIENCY – Due to the relatively slow rotational speed but large ...

with each size, ball mill was carried out for 12 h at three ... Effect of ball size and powder loading on the milling efficiency of a laboratoryscale wet ...

Ball Mill Download as Word ... grinding efficiency of the mill and. it is especially ... products are not up to the qualified size requirements. the ball of mill ...

Effect of ball size change on the performance of ... In order to optimize ball size distribution inside the mill, ... for one of the ball mills and its efficiency in ...

WhatsApp)

WhatsApp)