WhatsApp)

WhatsApp)

Official FullText Paper (PDF): THE MODEL FOR OPTIMAL CHARGE IN THE BALL MILL

The Difference Between the Ball Mill and Rod Mill Essay wang Rod mills are very similar to ball mills, except they use long rods for grinding media. ...

The crop load of ball mill. It =ore + mill medium +water. But usually, it was used in a percentage formation. So how to calculate this percentage. I know this is ...

TECHNICAL NOTES 8 GRINDING R. P ... The motion of an individual ball in the charge is ... The effect of mill charge is primarily through the shifting of the center ...

Feb 16, 2016· More Details: Manual design of SAG/ball/rod mill foundations, Structural Any .

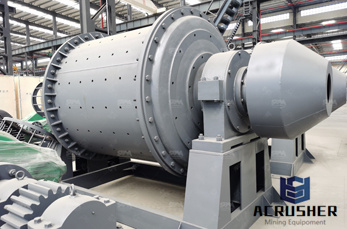

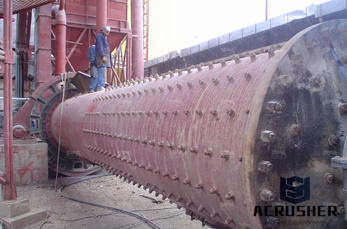

ball mill ball charge chute_Ball Mill ZonedingThe ball mill is a key equipment to grind the crushed materials, which is widely used in the manufacture industries ...

Ball charge calculation for ball mill free eBooks download Ball charge calculation for ball mill download on Allbookez free books and . >>Chat Online

Machinery and Equipment buys and sell Used Ball Mills for mining and minerals ... Hardinge ball mill, 11''6" ( m) diameter ... Unit has charge/discharge with ...

Grinding Ball Charger. Automatic ball charging equipment continuously meters grinding balls into the mill according to control parameters such as power draft, ball ...

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering ...

Mill charge in grinding ball mill circuits 1333 The piezoelectric strain transducer The first application of piezoelectric strain transducers, in 1982, involved force ...

– Monochamber mill power: it calculates the theoretical absorbed power of the . This calculator is a good start to evaluate the grinding ball charge after mill .

Ball charge analysis. Ball charge makeup. ... Sizing equipments and mill''s optimization are the job of material suppliers and experienced engineering offices.

About the Media Charge_Optimal Ball Size Spreadsheet ...Scope : The Media Charge_Optimal Ball Size spreadsheet was designed to estimate the ideal...

Ball mill Wikipedia. A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing widely used in production lines for powders such ...

A numerical tool known as the discrete element method (DEM) is used to study the motion of the ball charge in ball mills. In particular, the motion of individual ...

3 SAG mill (8 – 15% ball charge) Variable competency ore 4 High ball charge SAG mill (15 to . Increase the mill load by decreasing the mill speed, ...

The ball charge in ball mill is an important factor influencing working efficiency of ball mill. Then, how to determine the ball charge of ball mills?

Ball mills normally operate with an approximate ball charge of 30%. ... W is the work index measured in a laboratory ball mill (kilowatthours per metric or short ton)

The theoretical critical speed of a ball mill is the speed at which the centrifugal force is ... Although the amount of the media charge is application dependent, ...

How to Calculate a Ball Charge Load Level | Mining MetallurgyHow to Calculate a Ball Charge Load Level. ... Grinding Mills; Investing in Mining; Making

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Modification of the Ball Charge: This calculator analyses the granulometry of the material inside the mill and proposes a modification of the ball charge in order to ...

grinding media charging ball mill. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any size ...

WhatsApp)

WhatsApp)