WhatsApp)

WhatsApp)

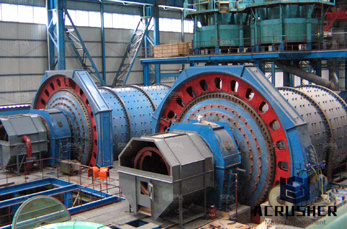

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed. Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement Plant.

Cement mill,Wikipedia, the free encyclopedia A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is ...

Mill Critical Speed Determination The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shell''s inside surface. This is the rotational speed where balls will not ...

A typical process of manufacture consists of three stages: grinding a mixture of limestone and clay or shale to make a fine "rawmix" (see Rawmill); heating the rawmix to sintering temperature (up to 1450 C) in a cement kiln; grinding ...

Used Cement Equipment Machinery and Equipment We offer complete used cement equipment including complete cement plant. ... Raymond Impact mill, Model 83, IMP Mill, driven by 400 HP motor, 893 RPM, 460... More details » Get Price

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement. The mill may operate in either open or closed circuit and with or ...

Selection Sheet Eaton Ball mills These mills use forged steel balls up to 5 inches ... Use of a clutch permits the mill motor to be ... The required clutch torque is calculated from the power rating of the mill motor, clutch shaft rpm ...

BALANCE THIS! Engineering Dynamics Figure 3 shows how the principal axis of inertia differs from the axis of rotation, but which was installed in the finish mill at a cement plant. The separator was Get Price Online IMPROVED ...

Cement mill Wikipedia, the free encyclopedia The critical speed (rpm) is given by: nC = /√d, where d is the internal The efficiency of the early stages ... Correlations for the Grindability of the Ball Mill As a DspaceNITR

Conversion to a twocompartment cementmill x m, 2 x 1250 kW Conversion to a twocompartment cementmill x m, 1900 kW Conversion to a onecompartment ballmill x m, 1500 kW Get more info ...

2017/02/07· how can we calculate the rpm of ball mill 3 Ways to Calculate RPM wikiHow How to Calculate RPM. ... You can relate the RPM of an object turned by wind to ... Calculate the RPM of the driven gear. How we figure this ...

Milling tools to clean out restrictions and damaged casing, liners, or tubing, with string taper, conductor taper, bladed junk, conebuster, pilot, and section mills. ... Clean out restrictions with tools for light to heavy milling Conductor ...

Cement mill Wikipedia A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills .

EXPERIENCE WITH SYNCHRONOUS AND SLIP RING INDUCTION MOTORS DRIVING CEMENT MILLS Table of contents Section Page 1 Abstract 3 2 Introduction 3 3. Ball mill and motor 3 Ball mill ...

Working principle : Rotation of cylinder is done at relatively speeds that allows balls to cascade through mill base and in turn achieve grinding/dispersing of materials Rotation of cylinder is normally between 4 to 24 RPM ...

A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently... Get Price Online A Matlab/Simulink framework for PLC controlled ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical ...

ball mill for cement plants ball mill for cement plants. How To Calculate Rpm Of Mill In Cement Plant. cement mill separator efficiency calculation. How To Calculate Cement Mill Separator ... Read more

10 MW coupling combination with lockup clutch Cement. The first such coupling is scheduled to be shipped to a cement manufacturer in the southern part of the To start up a ball mill requires a very high torque ( Online ...

ball mill for cement grinding Versatile system based on standard modules 2 The ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement. Online service » Balancing Equipment: a ...

ABSTRACT In cement plants, proper specification and supply of AC induction motors is critical to project schedules and providing efficient production. This paper focuses on the selection of AC induction motors for cement mill

Full Text RS Publication Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant .... top side steel ball size M = 127 mm; mill speed actual ... Product Application by Industry (X) Eaton Corporation Mill rpm.

cement mill mottor hp and rpm 6292 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our ...

Correlations for the grindability of the ball mill as a. time of grinding, particle density, and speed of the ball mill (rpm). An attempt has been ink, rubber, textiles, sintering, cement and limestone, powders for theChat Online Or Get ...

WhatsApp)

WhatsApp)