WhatsApp)

WhatsApp)

J. Cent. South Univ. Technol. (2010) 17: 750−754 DOI: /s11771−010−0551−z Twostep flotation recovery of iron concentrate from Donganshan carbonaceous iron ore YIN Wanzhong() 1, HAN Yuexin(), XIE ...

Iron process iron ore flotation beneficiation in india YouTube Oct 2, 2012 . National Metallurgical Laboratory Technology Offer: sale of. Live Chat Froth flotation Wikipedia Illustrative, the flotation process is used for purification of ...

Influence of water resources and metal ions on galena flotation of Rosh Pin ore for pyrite—cyanide is commonly employed to depress pyrite (Fuerstenau, 1982). At Rosh Pin (southern Namibia), valuable minerals, such as ...

flotation of iron ore influence of clay | Solution for ore mining Clay Potash Removal of clay from sylvite . For flotation of iron ore: Atrac® Lilaflot® Case Study . tive influence of flotation chemicals on the pelletizing. Process For ...

2016/01/02· Indian low grade iron ores mostly contain quartz, gibbsite, and clay as the major impurities. Depending upon the ore characteristics, in many instances froth flotation has to be used to recover the hematite and other iron ...

flotation of iron ore influence of clay | Solution for ore mining As a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate ...

7 Flotation of iron ore For more than 25 years, we have been developing flotation systems both for hematite and magnetite type iron ores and are now the leading company in this area. The use of silica flotation has increased in recent ...

Collector for flotation of iron ore AkzoNobel, For more than 25 years, AkzoNobel has been developing flotation systems both for hematite and magnetite type iron ores, and are now the leading company in. Contact

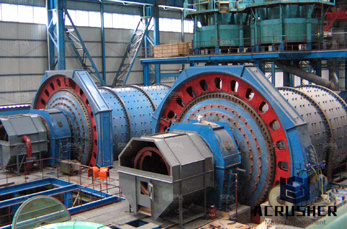

factors influence ore grinding mill PITTS Modern School factors that influence grinding media to ore ratio « mine quarry Cachedfactors ... The Factors ... lithium mineral ore grinding sher, Grinding ... lithium mineral ore grinding. ...

ore flotation cell project viability ore flotation cell project viability Clay Crusher Agitair Flotation Cells Crusher Mills, DRI GRINDING Stone Crusher Project Viability; Clay Crusher Agitair Flotation Cells. agitair flotation machine,flotation ...

Processes for phosphorus removal from iron ore a, Phosphorus can be removed from iron ore by very different routes of treatment, The articles surveyed cite removal by physical processes (flotation and selective, Based on results ...

what is iron ore flotation Mining Equipment Manufacturer And Distributor ... Essentially, iron ore flotation employ two types of collectors: anionic and ... Get More Detailed. iron ore flotation. » Learn More iron ore flotation process iron ...

AkzoNobel is a leading global supplier of flotation reagents and collectors for industrial minerals and iron ore applications. It has gained its leadership position by being at the forefront of the advanced colloid and surface chemistry upon ...

High clay ores – a mineral processing nightmare — Australian . . uranium, lead zinc, iron ores and nickel projects. Clays have a major impact on . effect for very heavy clay ores, the ore . Flotation: High clay ores result in ...

Clay Crusher Zinc Concentrate Bulgaria Zinc Concentrate Mining Bulgaria,Zinc Concentrate Crushing . Zinc Concentrate Mining Bulgaria,Zinc Concentrate Crushing . Ore into the crusher of PE series jaw crusher ...

Froth flotation is considered to be the most widely used method for ore beneficiation. In ore beneficiation, flotation is a process in which valuable minerals are separated from worthless material or other valuable minerals by inducing ...

With the depleting reserves of highgrade iron ore in the world, froth flotation has become increasingly important to process intermediate and lowgrade iron ore in an attempt to meet the rapidly growing demand on the international ...

Control of clay minerals effect in flotation. A review Hasan Ali Taner1,a, and Vildan Onen1 1Selcuk University, Department of Mining Engineering, 42075 Konya, Turkey Abstract. The increased exposure to low grade ores highlights the ...

copper conventional flotation separation Iron ore dressing plants Coal ore dressing Flotation separation process polymetallic iron ore Crusher Applications Iron ore concentrate flotation process Crusher in basalt aggregate ...

Froth Flotation Of Iron Ores With the depleting reserves of highgrade iron ore in the world, froth flotation has become increasingly important to process intermediate and lowgrade iron ore in ... » Learn More Iron ore flotation, M. Ma ...

1 1 Froth Flotation – Fundamental Principles Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces in a mineral ...

The higher solubility of ferrous iron allows a small proportion of the hydrated iron oxides coating the clay to be removed in solution. Ozone and chlorine may be used to improve brightness by oxidising organic matter. There is an ...

Clay processing plant Clay crusher, clay grinding mill, flotation machine, magnetic separator is widely used in clay processing plant for clay powder making ... In ultrafine mill, the clay is grinded combined with wet or dry method.

2011/08/15· High clay ores – a mineral processing nightmare — filed under: Print Edition by The Australian Journal of Mining — created Aug 15, 2011 11:06 AM Filtering is very difficult with high clay ores. ...

WhatsApp)

WhatsApp)