WhatsApp)

WhatsApp)

Loesche Mills for cement raw material. 2 Cement raw material has been almost exclusively ground in roller mills (vertical airswept grinding mills) since the second ...

History. The history of the development of the technology of raw material grinding defines the early history of cement technology. Other stages of cement manufacture ...

JK Cement Ltd of India has contracted ThyssenKrupp Polysius to supply three new grinding plants equipped with POLYCOM highpressure grinding rolls. The...

Cement is the basic ingredient of construction and the most widely used construction material. Its manufacturing includes extraction, proportioning, grinding,

cement raw material grinding process About jade CCTV News CNTV English. About jade. ... speckled or streaky material. It is not until the cutting process ...

According to statistics, over 60% cement plant power will be consumed to grind materials in dry process cement production line. Among which, over 30% is used for raw ...

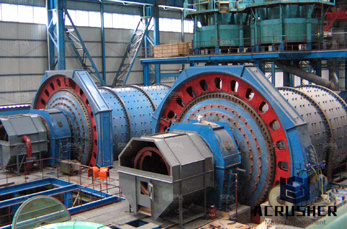

CHAENG | Great Wall Machinery provides you:Slag Grinding Plant,Cement Equipment,Vertical Mill,Ball Mill,Rotary Kiln For Quarry, ... Raw Material .

Loesche Mills for cement raw material. 2 Cement raw material has been almost exclusively ground in roller mills (vertical airswept grinding mills) since the second ...

Cement Production, raw material and ingredients for cement... The main raw material to produce Portland cement are lime materials and clayey materials, and ...

CEMENT RAW MATERIALS PLANT SIZES. The coordinates of the grinding table diameter and number of rollers can be read off from the table. The x .

Raw material preparation aims to ... The production of one ton of portland cement requires more than ton of raw ... If raw material grinding is ...

Raw Material Grinding. The desired raw mix of crushed raw material and the additional components required for the type of cement, silica sand and iron ore, is ...

Grinding trends in the cement industry Cement Lime Gypsum. 10 Combination grinding system with roller press. ... 23 Raw material mill .

Manufacturing Process Of Cement. Quick ... method is used to reclaim and obtain high efficiency raw material ... yard/clinker silo for cement grinding.

roller press raw mill in cement. 3. ... A roller press is used for grinding of raw material, .... 3D model of a cement grinding plant with a ball mill, ...

Aug 26, 2016· Video embedded· This is a simple video slideshow, if you want to know more details, please click on our website , we will .

– Raw Materials for Cement Manufacture. Raw materials for cement manufacture. The first step in the manufacture of portland cement is to combine a variety ...

in cement: Grinding. ... ground to a fine powder in horizontal mills similar to those used for grinding the raw materials. The material may pass straight ...

Cement Kilns: Raw Material Preparation. Preparation of cement raw materials. the base of the drive shaft. For slurry grinding, output per pair of stones was 23 dry t ...

Extraction and blending Raw material grinding Raw material homogenisation Clinker production Cement grinding Conveying, packing, loading .

Grinding trends in the cement industry Cement Lime Gypsum. 2 Mill orders 2007/2008 according to mill types (OneStone) [3] 4 Types of mills for raw material grinding ...

These have been used for many years for the less exacting rawmilling ... have been used for cement grinding. ... that will deliver material of cement fineness.

Raw material grinding is one of the processes used to manufacture cement of highest quality.

Cement grinding Vertical roller mills versus ball ... easily obtained in raw material grinding in a ... when grinding cement than when grinding raw ...

WhatsApp)

WhatsApp)