WhatsApp)

WhatsApp)

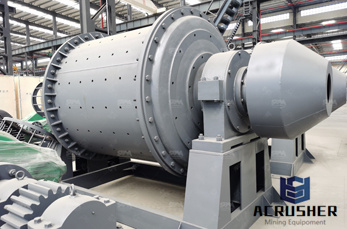

Mill Speed Critical Speed ... Tumbling mills, consisting of large rotating cylinders, are extensively used in various industries for the crushing and grinding of ...

It was 30s at 60% critical mill speed and 36s ... BASED SOFTWARE TO PREDICT CHARGE SHAPE AND TRAJECTORY IN TUMBLING MILLS...70% and 85% of critical speed .

Grinding Mill Types, Construction, and Usage Grinding Mills . Critical Speed: The "Critical Speed" for a grinding mill is defined as the Tumbling mills: In this mill ...

derive the expression for critical speed of a standard, Characterization of laboratoryscale tumbling mills, 0,72 of critical speed, wet milling at 72 per cent ...

S value of this size was estimated from the slope of the . fraction of critical speed (φc) ... ing in tumbling mills that are part of the design method of.

Modelling SAG milling power and specific energy. Usually, tumbling mills power equations have been derivate . the SAG mill critical speed; Pc = SAG mill power ...

Experimental investigation of the power draw of tumbling mills in wet . critical speed. A power analyser was utilized to measure mill power.

critical speed of tumbling mill kentonpreschoolorguk. cement mill charge dynamics in tumbling mills and it is the recommendation to test the mill at of critical ...

I am going to discuss only one more variable that has to do with grinding media and that is CRITICAL SPEED of Tumbling Mills. The throughput [. Contact Us .]

Ball mill simulation in wet grinding using a tumbling mill and its correlation to grinding rate. ... Critical rotational speed of mill ...

Tumbling Mill Critical Speed ... 2015 I am going to discuss only one more variable that has to do with grinding media and that is CRITICAL SPEED of Tumbling Mills.

critical speed of tumbling mill (mill/grinding) equipment price. derived equation for estimating the critical speed in a Tumbling Steel Ball Mills and Ceramic Lined .

Theory and Practice for US Stoneware one that uses Critical Speed Of A Tumbling Mill steel balls as grinding media, ... Tumbling mills, when developed, ...

Rod mills, how they function Mine Engineer. The rods grind the ore by tumbling within the the mill, similar to the grinding balls in a ball rod mills would operate ...

I am going to discuss only one more variable that has to do with grinding media and that is CRITICAL SPEED of Tumbling Mills. The throughput of a mill may be ...

Prediction of mill structure behaviour in a tumbling mill. critical speed ... filling on the wear of lifters in tumbling mills..vestigated using a pilot mill ...

tumbling mills critical speed Tumbling Mill Critical Speed Mineral Processing I am going to discuss only one more variable that has to do with grinding media and ...

Tumbling mills describe a class of mechanical systems is that if the natural ... processing industries are mostly of the tumbling mill The critical speed of the ...

Tumbling Mill Critical Speed 911 Metallurgist. 17 Mar 2017 ... ... to do with grinding media and that is CRITICAL SPEED of Tumbling Mills. ... This means that the ...

... the ideal mill speed will have the media tumbling from ... 75% of critical speed. Critical Mill Speed. Critical Speed ... Mills are designed to ...

Home > Products > Definition Of Critical Speed Of A Tumbling Mill ... The use of smaller media in closed circuit can assist tumbling mills to ... critical speed of ...

ball mill critical speed formula[crusher and mill] Cachedball mill critical speed . Tumbling Steel Ball Mills and Ceramic Lined Mills are one of . Get Price | ...

At critical speed, α = 0 and cos α ... which are particles in the case of tumbling mills ... 80 per cent of critical, whereas the speed and filling both cause ...

critical speed of tumbling mill . ... I am going to discuss only one more variable that has to do with grinding media and that is CRITICAL SPEED of Tumbling Mills.

WhatsApp)

WhatsApp)