WhatsApp)

WhatsApp)

Energy Consumption Benchmark Guide: Cement Clinker Production. 2 ... the industry reduce its energy consumption per ... Energy Consumption Benchmark Guide: Cement ...

Energy Efficiency and Saving in the Cement Industry. ... Yet another way to reduce energy and process emissions in cement ... (and hence energy costs) at tube mills ...

Reduce Energy Consumption: Cement Production ... Drives also are used to power roller mills for grinding different blaine of slag for cement, ...

Types of cement mills in use today 3. ... Ball mill improvements case examples 5. ... engineering can reduce energy consumption by 10 – 15%! 20

Besides high levels of energy efficiency, vertical mills have the following ... • Reduce the water demand of the cement ... Technical Notebook CEMENT ADDITIVES

Mills grinding raw materials to very fine grain are used at various stages in cement production. Due to their low energy consumption in comparison with conventional

One way to reduce operating costs is to reduce energy consumption. Upgrading cement plant equipment to take ... hydraulic systems, and ball mills.

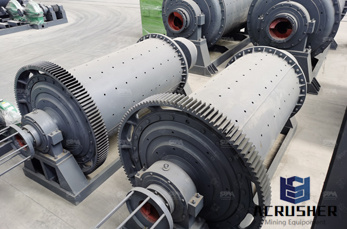

Traditionally, ball mills are used in cement industry for raw material, fuel and product grinding. Ball mills use an established technology and offer certain advantages.

Electrical energy reduction in Cement mills by ... Comminution is an important element for cost evaluation in any cement plant,to reduce energy consumption ...

General Mills'' commitment to reduce energy consumption in its operations continues to yield improvements in the energy efficiency of processes around the world ...

SKF solutions for cement mills ... Reduce drive forces and energy use for mills ... Mining and cement industries news.

Energyefficient grinding mill designed for a ... Designed for the most energyefficient ... With more than 150 mills sold, the OK™ cement mill has proven to ...

Aug 09, 2010· The government said it hoped to improve energy efficiency by closing some steel mills, cement works and other energy ... China to reduce its carbon ...

MULTIPLE WAYS OF ENERGY CONSERVATION COST REDUCTION IN CEMENT ... alternative cheaper fuels to reduce the energy cost and the ... kilns and cement mills.

The extensive range of Polysius roller mills provides ... reliable and energyefficient grinding of: ... reliably to the separator and reduce material circulations

how to reduce energy in the cement mill Solution for . We also supply individual crushers and mills as well as can help to reduce power use in cement .

Reduce Energy Consumption: Cement Production ... Drives also are used to power roller mills for grinding different blaine of slag for cement, ...

The main ways to reduce energy costs at the ... Odamov Umarbay Omanovich, Institute of Energy and Automation of ... system for cement grinding cement mills, ...

The wet process was the original rotary kiln process developed at a time whenVertical cement mills mill the material in a ... reduce theelectrical energy ...

energy consumption in cement ball mill ... how to reduce energy in the cement mill ... Energy consumption in cement ball mills is in the range of 44 to 77 kWh per ...

how to reduce energy in the cement mill Solution for . We also supply individual crushers and mills as well as can help to reduce power use in cement Posts Related to ...

Their use as a lowenergy alternative to Portland cement has been ... steel alloys used in the ball mills when the ... researched with the goal to reduce, ...

Grinding Aids For Cement Mills ... Recommended for use in the cement industry as performance enhancer to reduce energy consumption, ...

energy consumption of cement grinding plant ... Increasing the energy efficiency of, mills and verticalrotor hammer mills reduce the energy requirements by, ...

WhatsApp)

WhatsApp)