WhatsApp)

WhatsApp)

Grinding in Ball Mills: Modeling and Process Control ... ball size distribution); • speed of ... An important characteristic of an industrial ball mill is its ...

ball mill actual rpm on crtical speed_ Ceramic MaterialsBall mills are the most commonly used piece of equipment for milling However, vibratory apply a highspeed ...

Optimum choice of the makeup ball sizes for maximum throughput in tumbling ball ... makeup ball size on the mill ... mill as a fraction of critical speed ...

ball mill actual rpm on crtical speed_ Ceramic MaterialsBall mills are the most commonly used piece of equipment for milling However, vibratory apply a highspeed ...

is home to a collection of both free and subscriptionbased calculation tools to ... including for SAG millball mill ... Size analysis; Sliderule;

Ball Mill Critical Speed. Cargado por Danielito Bonito. Intereses ... The Effect of ball size on the energy efficiency of hybridpressure toll mill/ball mill ...

calculate critical speed ball mill. ... Size Reduction and Mill Speed Critical . Calculating how fast a Jar needs to spin is a little tricky, but simple one you know.

The Effect of ball size on the energy efficiency of hybridpressure toll mill/ball ... Documents Similar To Ball Mill Critical Speed Skip carousel. ball mill. Ball ...

calculate critical speed ball mill. ... Size Reduction and Mill Speed Critical . Calculating how fast a Jar needs to spin is a little tricky, but simple one you know.

Ball Mill Ball Size. Size Reduction Equipment | Paul O. Abbé ... To achieve a reasonable efficiency with ball mills . the critical speed of any ball mill.

Dec 23, 2013· Practical 1 : Ball Milling. ... The longer the time of grinding, the faster the process of particle size reduction. Speed of the ball mill (rpm): ...

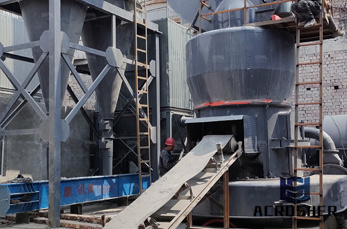

MIKRONS Ball Mill form a significant class of equipment used in the field of size reduction. The slow rotational speed combined ... the critical speed of any ball mill.

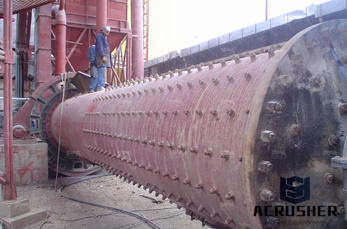

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell''s inside ...

Effect Of Ball Size On The Critical Speed Of Ball [ 7154 Ratings ] The Gulin ... down to the particle size speed of any ball mill. Most ball mills

STEEL BALL MILLS : j ... Mill Size (Dia. X . Length) ... shows typical paste charges based on 50% ball charge and mill speed at 60% of Critical ...

Theory and Practice for . Jar, Ball and Pebble Milling . ... a ball mill is referred to as ... Critical speed in RPM is calculated by this relationship:

AMIT 135: Lesson 7 Ball Mills ... number, ball size distribution); Speed of mill rotation; Slurry ... after reaching a critical speed, the mill charge clings to the ...

Mill Speed Critical Speed Paul O. Abbe Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

critical speed of a ball mill and ball size – Grinding Mill . Posted at: July 30, 2012. Ball mill – Wikipedia, the free encyclopedia The critical speed can be ...

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

ball mill calculations critical speed ... In this study, the effects of ball charge, powder filling, mill speed and ball size on model parameters ofcumulative, ...

A ball mill is a type of grinder used to grind and blend ... size reduction is done by impact as the ... The grinding works on the principle of critical speed.

The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball. For R = 1000 mm and r = 50 mm, n c = rpm.

WhatsApp)

WhatsApp)